Heat Power Capacity: 300000-12000000 KCAL/H (350-14000 KW/H)

Rated Working Pressure: 1.1MPa

Thermal Oil Working Temperature: ≤320℃

Fuel Type: Coal, Wood Chips, Wood Logs, Sawdust, Rice Husk, Sugarcane Bagasse, etc.

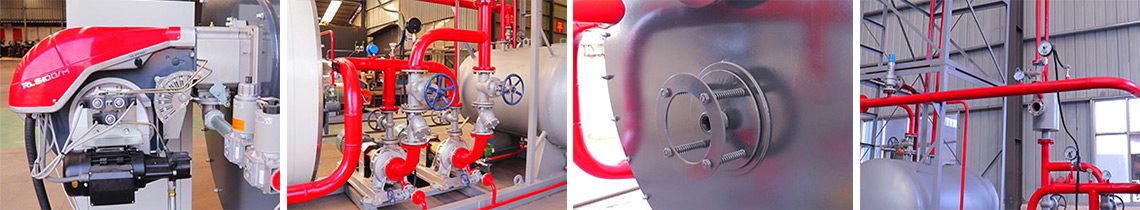

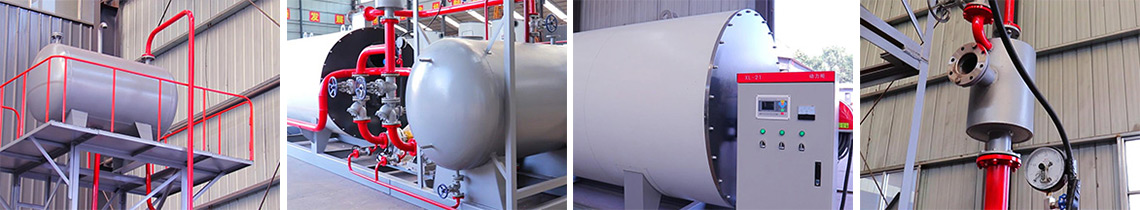

YY (Q) W series gas oil fired thermal oil boiler is a quick assembly and full automatic thermal oil boiler, adopts a three-pass structure, full corrugated coil. The heat carrier is heat conduction oil, rated working pressure 1.1MPa, working temperature ≤350℃. After the boiler arriving at the users’ site, only need to consider filling the heat conduction oil, connect fuel (gas or oil), and electricity source.

Petrochemical, Textile Printing/ Dyeing, Plastic Industry, Rubber Plant, Food Processing, Wood Processing, Asphalt Heating, Carton Production, Vegetable Dehydration, Baking Varnish, Casting Sand Mold Drying, etc.

High-Quality Control: In manufacturing processes, we have to adopt steel strength test, automatic steel cutting/ plate rolling/ welding, 100% x-ray welding check, magnetic particle check c-scan ultrasonography check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency test, etc. to make sure all finished products are qualified.

Durable Coil Heater: YY (Q) W series adopting high-quality corrugated coil to carry the heat conduction oil, increase the heat transfer area, the reasonable gap between coil tubes to fit the hot expansion and cold contraction. Average coil tubes’ working life is more than 17years.

Automatic Safe Operation: Full automatic PLC ON/OFF controller, free settable thermal operation temperature and working time, automatic temperature control, automatic over-pressure/ over temperature interlock chain stop protection, visible system’s working states (burner’s states, system working pressure/ oil temperature) on screen, etc.

| Model | YY(Q)W-350 | YY(Q)W-500 | YY(Q)W-700 | YY(Q)W-1000 | YY(Q)W-1200 | YY(Q)W-1400 | YY(Q)W-1800 | YY(Q)W-2100 | YY(Q)W-2400 | ||

| Heat Power | KW | 350 | 500 | 700 | 1000 | 1200 | 1400 | 1800 | 2100 | 2400 | |

| KCAL | 300000 | 420000 | 600000 | 850000 | 1000000 | 1200000 | 1500000 | 1800000 | 2000000 | ||

| Medium Woring Temperature | ℃ | ≤350 | |||||||||

| Available Fuels | / | Gas (natural gas, lpg, biogas) Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) |

|||||||||

| Combustion Method | / | Pressurized combustion in chamber | |||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working temperature | |||||||||

| Dimension | L | mm | 2100 | 2200 | 3240 | 3300 | 3830 | 4150 | 4600 | 5020 | 5080 |

| W | mm | 1390 | 1390 | 1470 | 1670 | 1770 | 1900 | 2000 | 2050 | 2200 | |

| H | mm | 2055 | 2055 | 2260 | 2480 | 2590 | 2790 | 3100 | 3080 | 3180 | |

| Weight | kg | 2580 | 3000 | 3700 | 5000 | 5800 | 6700 | 7800 | 8800 | 9800 | |

| Model | YY(Q)W-3000 | YY(Q)W-3500 | YY(Q)W-4700 | YY(Q)W-6000 | YY(Q)W-7000 | YY(Q)W-10000 | YY(Q)W-12000 | YY(Q)W-14000 | ||

| Heat Power | KW | 3000 | 3500 | 4700 | 6000 | 7000 | 10000 | 12000 | 14000 | |

| KCAL | 2500000 | 3000000 | 4000000 | 5100000 | 6000000 | 8500000 | 10000000 | 12000000 | ||

| Medium Woring Temperature | ℃ | ≤350 | ||||||||

| Available Fuels | / | Gas (natural gas, lpg, biogas) Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) |

||||||||

| Combustion Method | / | Pressurized combustion in chamber | ||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working temperature | ||||||||

| Dimension | L | mm | 5990 | 6560 | 7280 | 7800 | 8200 | 10000 | 11500 | 12000 |

| W | mm | 2420 | 2470 | 2570 | 3050 | 3050 | 3500 | 3650 | 3780 | |

| H | mm | 3180 | 3640 | 3760 | 3800 | 3800 | 4000 | 4200 | 4350 | |

| Weight | kg | 15500 | 17800 | 21500 | 25000 | 27500 | 32000 | 37000 | 42000 | |