Steam capacity: 0.5-20Ton/h

Working Pressure: ≤1.6MPa

Fuel Type: Gas (natural gas, LPG, Biogas), light oil (2#diesel, Kerosene), heavy oil (6# fuel oil, crude oil)

Application: Textile, Garment, Food & Beverage, Cement Curing, Disinfection, etc.

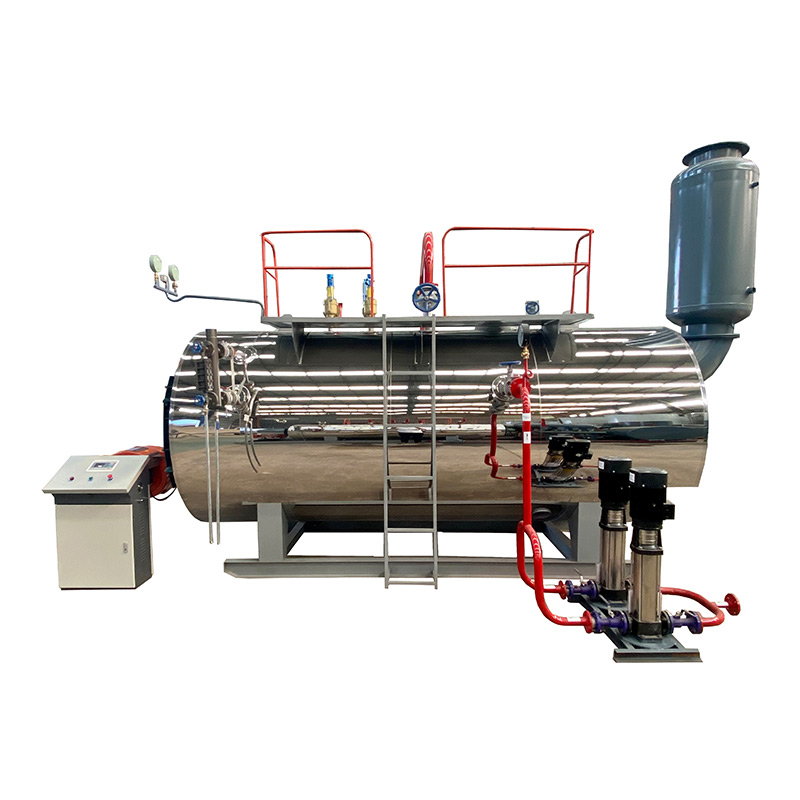

WNS series quick assembly gas and oil fired boiler, with classical shell, 3pass, and fire tube design. Contains boiler proper, burner, water level/ pressure control system, economizer, exhaust flue system, valves, etc. Due to their reliable quality and steady performance, WNS series boilers have become the most popular products worldwide.

Textile, Garment, Food & Beverage, Chemical Industry, Cement Curing, Disinfection, etc.

Special Structure and High Efficiency: Adopting corrugated furnace, threaded fire tubes, 3 fire-passes structure, full wetback design, markedly increased boiler’s heating area and heat transfer efficiency. It is equipped with renowned brand burners (BALTER, RIELLO, HOFAMAT, and ECOFLAM); also finned tube-type economizer can ensure boiler’s thermal efficiency up to 95%.

High-Quality Control: In manufacturing processes, we have adopting steel strength test, automatic steel cutting/ plate rolling/ welding, 100% x-ray welding check, magnetic particle check c-scan ultrasonography check, fluorescent penetrating check, hydraulic (water) pressure test, boiler thermal efficiency tested, to make sure all finished products are qualified.

Automatic Safe Operation: WNS series boiler is equipped with automatic burner ignition, automatic water-level control, automatic pressure control, automatic interlock chain stop protection, free settable working pressure, free settable ON/OFF time, visible system’s working states on screen.

Easy Maintenance: WNS series boiler uses full water back tube-sheets instead of traditional dry-back tube-sheet can avoid the dry-fire broken, and reduce the range of steel cooling contraction and hotting expansion. Also, we adopting openable smoke-boxes, users can replace the broken fire tubes conveniently.

| Model | WNS0.5 | WNS0.7 | WNS1 | WNS1.5 | WNS2 | WNS3 | WNS4 | WNS5 | WNS6 | WNS8 | WNS10 | WNS15 | WNS20 | ||

| Capacity | kg of steam per hour | 500 | 700 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 15000 | 20000 | |

| HP | 32 | 44 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 512 | 639 | 959 | 1278 | ||

| Pressure | Bar | ≤10 | ≤10 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | |

| Steam Temperature | ℃ | ≤184 | ≤184 | ≤194 | ≤194 | ≤194 | ≤194 | ≤194 | ≤194 | ≤204 | ≤204 | ≤204 | ≤204 | ≤204 | |

| Available Fuels | / | Gas (natural gas, lpg, biogas) Light Oil (2# diesel, kerosene) Heavy Fuel Oil (6# bunker C, fuel oil 380, fuel oil 180) |

|||||||||||||

| Thermal Efficiency | % | >92 | |||||||||||||

| Combustion Method | / | Pressurized combustion in chamber | |||||||||||||

| Control Method | / | PLC ON-OFF control, Adjustable working pressure | |||||||||||||

| Dimension | L | mm | 2950 | 3050 | 3250 | 3450 | 3880 | 4260 | 4800 | 4950 | 5490 | 6670 | 6980 | 7500 | 8200 |

| W | mm | 1550 | 1600 | 1770 | 1910 | 1900 | 2130 | 2200 | 2250 | 2250 | 2600 | 2600 | 3200 | 3400 | |

| H | mm | 1730 | 1790 | 2070 | 2200 | 2180 | 2450 | 2500 | 2500 | 2700 | 3100 | 3300 | 3560 | 4100 | |

| Weight | kg | 3700 | 4100 | 4800 | 5900 | 6800 | 9100 | 12500 | 14800 | 16200 | 19600 | 27400 | 38000 | 47000 | |